What is Resin 3D Printing?

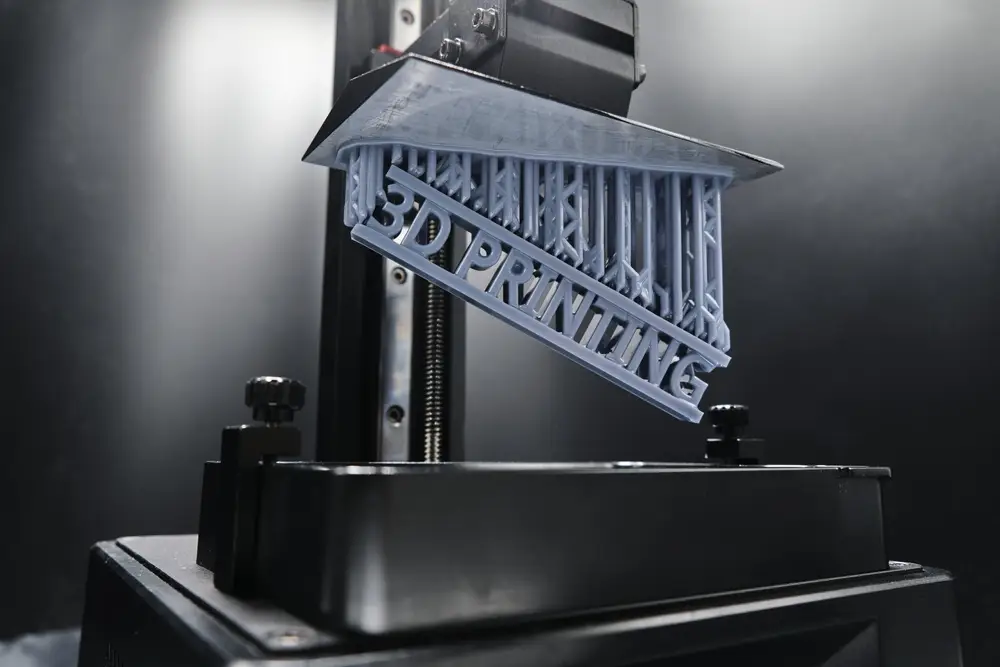

Resin 3D printing, also known as stereolithography (SLA) and digital light processing (DLP), is a technology that uses liquid resin cured by UV light to create highly detailed, smooth, and intricate models. Unlike FDM printing, which builds layers using melted plastic, resin printing hardens liquid material with precision, resulting in exceptional accuracy and fine surface details.

At Analog AM, we specialize in high-resolution resin 3D printing for projects that demand precision, smooth textures, and intricate designs. Whether you need functional prototypes, artistic models, dental applications, or jewelry prototypes, resin printing delivers unmatched quality and detail.

Why Choose Resin 3D Printing?

Resin printing is ideal for projects that require ultra-fine details and high accuracy. It is widely used in industries where aesthetic quality and intricate structures are crucial. Some of the key advantages of resin printing include:

✔️ High Precision – Perfect for intricate and delicate designs, down to the smallest details.

✔️ Smooth Surface Finish – No visible layer lines, making it ideal for aesthetic and presentation models.

✔️ Complex Geometries – Capable of fine, detailed structures that other printing methods can’t achieve.

✔️ Material Versatility – Wide range of resins with different properties, including rigid, flexible, and heat-resistant.

✔️ Exceptional Print Quality – Produces parts that look and feel like injection-molded products.

At Analog AM, we ensure that every resin print meets the highest standards of quality, accuracy, and durability.

Industries That Benefit from Resin 3D Printing

Jewelry & Fashion

Jewelry designers use resin 3D printing to create precise wax molds for casting, allowing for highly detailed and custom-made pieces.

Dental & Medical Applications

Resin printing is widely used in dentistry for creating custom dental models, crowns, aligners, and surgical guides. Its biocompatible resins make it a reliable choice for medical applications.

Miniatures, Art, and Figurines

Artists and collectors love resin printing for creating detailed sculptures, miniatures, and action figures with perfectly smooth finishes and sharp details.

Engineering & Product Prototyping

For engineers and product designers, resin printing provides accurate prototypes that mimic the final product’s look and feel, making it easier to test and refine designs before production.

Consumer Electronics & Functional Parts

Resin printing is used in the electronics industry for custom casings, enclosures, and small intricate parts where precision is critical.

Our Resin 3D Printing Process at Analog AM

At Analog AM, we follow a step-by-step process to ensure that every resin print is detailed, functional, and optimized for its intended use.

1. Understanding Your Requirements

We start by discussing your design needs, functionality, and material preferences to determine the best resin type for your project.

2. 3D Modeling & Pre-Processing

If you already have a 3D model, we check and optimize it for resin printing compatibility. If not, our expert designers can help create a high-resolution model ready for printing.

3. Choosing the Right Resin Material

Different resin types are available based on your project’s needs:

🔹 Standard Resin – Ideal for prototypes and visual models with sharp details.

🔹 Tough & Durable Resin – Designed for functional, impact-resistant parts.

🔹 Flexible & Elastic Resin – Used for rubber-like properties in soft parts.

🔹 High-Temperature Resin – Perfect for heat-resistant applications.

🔹 Dental & Biocompatible Resin – Safe for medical and dental uses.

4. Printing & Post-Processing

Once printed, resin parts require post-processing, including washing, curing, and support removal to achieve the final finish. We ensure smooth, professional-quality results in every print.

5. Final Touches & Quality Check

Before delivery, each print undergoes a final quality inspection to ensure it meets accuracy, strength, and aesthetic requirements.

Why Choose Analog AM for Resin 3D Printing?

✅ Ultra-High Detail – Perfect for intricate designs, jewelry, and small precision parts.

✅ Smooth & Polished Surfaces – No rough edges or visible layers, giving a professional finish.

✅ Wide Range of Resins – Choose the right material for strength, flexibility, or heat resistance.

✅ Fast & Reliable Production – Get your parts printed and delivered quickly without sacrificing quality.

✅ Expert Support & Consultation – Need help selecting the right resin or refining your design? We guide you through the process.

Start Your Resin 3D Printing Project with Analog AM

Resin 3D printing is the perfect solution for high-precision, smooth, and complex designs. Whether you’re a jewelry designer, medical professional, engineer, or artist, Analog AM provides top-tier resin printing services tailored to your needs.

📩 Ready to print your next high-detail project? Contact us today and let’s bring your vision to life!